The Design Features and Operation Points of Spiral Duct Machine

Apr 16, 2025

Spiral duct machines are essential equipment in the HVAC duct manufacturing industry, known for their efficiency, automation, and precision. Understanding their design features and proper operation points is crucial for maximizing productivity and ensuring consistent product quality. At Hecheng Source Machinery, we have specialized in the production of spiral duct forming machines for nearly a decade, serving clients in over 80 countries.

Design Features of Spiral Duct Machines

1. Robust Frame Construction

The machine is built with a solid steel frame to minimize vibration during operation and ensure stability even during high-speed production. This guarantees long-term durability and reliable performance.

2. High-Precision Forming Molds

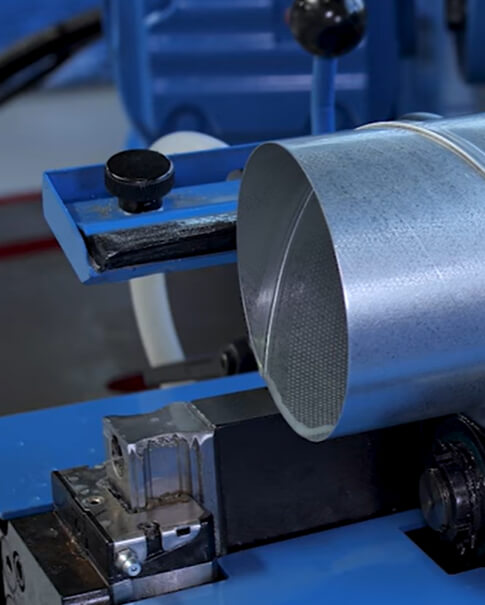

Precision molds are used to form ducts of various diameters with tight tolerances. These molds are customizable and made from wear-resistant materials for long-lasting use.

3. Automatic Cutting System

Equipped with an automatic cutting mechanism, the machine can cut the duct to preset lengths accurately, reducing manual labor and improving efficiency.

4. Touch Screen Control Panel

A user-friendly interface allows operators to input duct sizes, production speed, and cutting length with ease. This helps in reducing setup time and operational errors.

5. Adjustable Diameter Range

Most machines support a wide diameter range, from small to large spiral ducts, making them versatile for different applications.

6. Material Compatibility

Spiral duct machines can handle galvanized steel, stainless steel, aluminum, and other ductwork materials, providing flexibility in manufacturing.

Operation Points for Optimal Performance

1. Pre-Operation Inspection

Check for loose parts, proper lubrication, and correct tool settings before starting the machine. Regular inspection helps prevent unexpected downtime.

2. Accurate Material Feeding

Ensure that coil material is aligned correctly and fed smoothly into the machine to avoid deformation or misalignment during forming.

3. Monitor Cutting System

Keep the cutting blades sharp and monitor the cutting accuracy. Replace blades as needed to maintain clean edges.

4. Operator Training

Train personnel on machine control, emergency stops, and safety procedures. Skilled operators contribute significantly to safe and efficient production.

5. Regular Maintenance

Perform scheduled maintenance on mechanical parts, electrical systems, and lubrication points to extend machine life.

Understanding the key design features and proper operation techniques of spiral duct machines can greatly enhance manufacturing efficiency and product quality. Choosing the right equipment and using it correctly ensures optimal results and long-term performance.

At Hecheng Source Machinery, we deliver well-designed, reliable spiral duct machines supported by comprehensive technical service and international experience. Contact us to explore the right solution for your duct manufacturing needs.

A spiral ducting machine is a specialized type of machinery used to create spiral ducts that are used in heating, ventilation, and air conditioning (HVAC) systems. The spiral duct is formed by feeding a tube of duct material through a set of rollers that shape the material into a spiral shape. The edges of the spiral are then joined together with specialized welding or fastening techniques. The finished spiral ducts offer superior airflow, noise reduction, and energy efficiency compared to traditional rectangular ductwork.

HS Code :

8455229090

Min. Order :

One Set

Manufacturing Time :

Almost IN STOCK

Payment Terms :

TT,LC,West Union etc

Packing Method :

Exporting wooden box

Quality Guarantee Period :

18 month from B 'L issued date

Annual Production Capacity :

200 sets machines

CUSTOMER DESIGN OR OEM :

Accepted